Basic Info

| Pressing Layer | Single Layer |

| Work Mode | Continuous |

| Controlling Mode | Control Cabinet |

| Certification | CE |

| After-sales Service | 12 Months |

| Material | Sawdust,Rice Husks,Peanut Shells |

| Final Product Shape | Hexagonal ,Square |

| Machine Weight | 650kg |

| Transport Package | Wooden Case |

| Specification | 1580*660*1650mm |

| Trademark | SL |

| Origin | China |

| Production Capacity | 250-300 Kg Per Hour |

Product Description

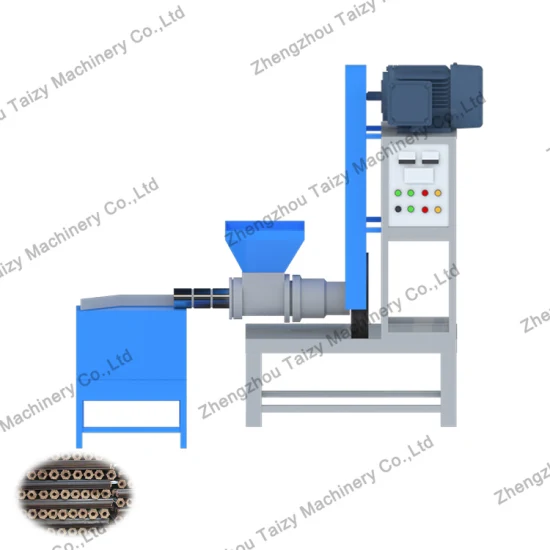

The industrial sawdust briquette machine is also known as the wood briquettes making machine and pini kay extruder machine. This biomass briquettes machine is mainly used to extrude rice husks, sawdust, and wood powder into solid rods under higher density under high temperature and high-pressure conditions.

The sawdust briquette machine adopts electric heating, which can pyrolyze the lignin in the raw materials. So that the raw materials such as rice husk or sawdust can be bonded together. In addition, the screw propeller inside the briquettes extruder machine can extrude the sawdust from the molding die to produce solid biomass rods of various shapes. The produced biomass briquettes can usually be used directly as fuels, or they can be reprocessed to make charcoal products.

Sawdust, crop straw powder(corn stalk, soybean stalk, sorghum stalk, cotton stalk, rape stalk, peanut seedling, sunflower stalk), rice husks, grass, shrub branches, bamboo and wood cutting head, material head, bagasse, coconut shell powder, bamboo powder, palm kernel shell powder, etc. Almost all wood waste materials and farmland straws can be used to process sawdust briquettes. But these raw materials need to be pre-processed first, such as crushing and drying, before they can be processed by the sawdust briquettes maker.

Machine Structure

Motor. The motor power of the briquettes-making machine varies according to different models, generally between 18.5-22kw. The motors used in our factory are all copper core motors with sufficient power and long service life.Charging hopper. The feed port of the machine can be added with an extended funnel, which is convenient for feeding and using. The screw inside the feed inlet can push the material forward.PLC controller. When using large models of machines, we usually equip this electric control cabinet. Especially when the machine is used in the charcoal production line, the electric control cabinet can ensure the safe use of electricity.Heating part. The heating ring is usually sleeved on the outside of the forming cylinder. These heating coils are vulnerable parts. When customers purchase the equipment, they usually purchase many heating coils for spare use.Extruding molds. The extrusion molding part of the machine is mainly determined by the molding cylinder. The forming cylinder can be replaced with different shapes and different diameters.

Product ParametersModel | Power | Capacity | Weight |

ZBJ-50 | 15kw | 200-250kg/h | 550 |

ZBJ-50 | 18.5kw | 250-300kg/h | 600 |

Packaging & ShippingOur Factory

Our Customer