Waste Magnesium Metal Powder Recycling Hydraulic Vertical Four Column Briquette Making Machine

Description

Basic Info

| Model NO. | Y83-3600 |

| Production | 2.5~4.5tons/Hrs |

| Operation Mode | Automatically by PLC |

| Labor Required | 1-Person |

| Energy Consumption | Energy Saving and Environmental Protection |

| Customer Layout Designing | Supply for Free |

| Raw Material Test | Free |

| PLC Brand | Siemens, Mitsubishi or Customized |

| Material Fluid Collection | Included |

| Conveyor | Included |

| Screw Feeding | as Per Customer Required |

| Transport Package | Seaworthy or Customized |

| Trademark | ACESUN |

| Origin | China |

| HS Code | 84629190 |

| Production Capacity | 500sets/Year |

Product Description

Application

Y83 series Briquetting PressUnder the situations that it is not heated or added with additives, the scrap metal briquette press is capable of pressing diversified granular and powdered materials into high density cylindrical briquettes that are hard to become loose. It processes the waste materials like scrap steel, cast iron, pig iron, aluminum ingot, waste copper, magnesium, titanium and molybdenum for secondary fusion instead of using them directly.Our product makes it easy to recycle, smelt, store and transport the scraps. Moreover, it reduces the cost and melting loss so that the utilization rate of the waste is increased. This product is commonly seen in the aluminum alloy section plant, steel, aluminum and copper casting plants, etc.

Structural Style

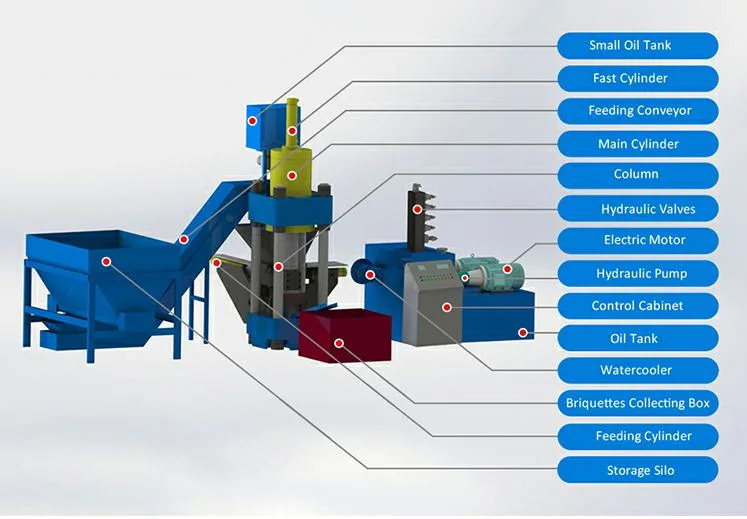

This chip briquetting press varies in vertical and horizontal structure. Therein, the vertical product is equipped with or without feeding cylinder. The diameter of briquette can be designed in the designated range according to users' need. If there is no special requirement, the machine that pressing force less than 200ton is structured with welded frame. With the pressing force ranging from 200ton to 315ton, the machine is designed with welded frame or four columns. Yet the product pressing force over 500ton uses four columns.

Operating Methods

Our scrap metal briquette press can be designed for manual operation, single automatic operation or continuous automated manipulation. Users are free to select the PLC system for controlling the automatic operation as they want.

Features

1. Due to the hydraulic drive, the machine runs stably and reliably. 2. The vertical product needs simplified foundation yet the horizontal machine doesn't need. 3. Under the control of PLC, this chip briquetting press possesses strong anti-interference capacity, high level of automation and ease of operation. 4. Based on the demands of users, this product can be equipped with automatic feeding and discharging devices to improve the production efficiency and decrease the labor intensity. 5. It can be powered by diesel engine when there is no electricity at all.

Product Parameters

Specifications:

| Model | Inner dia.of main cylinder | Briquette size (mm) | Briquette density (T/m3) | Briquettes/min | Production(T/shift) | Power(kw) | Operationalmode |

| Y83-2000 | 280 | φ80×(60-80) | ≥5 | 4~5 | 3~5.5 | 18.5 | PLC automatically |

| Y83-2500 | 320 | φ90×(60-80) | ≥5 | 4~5 | 5~8 | 30 | |

| Y83-3150 | 360 | (φ90~φ110)×(70-100) | ≥5.5 | 4~5 | 7~10 | 30 | |

| Y83-3600 | 400 | (φ100~φ120)×(70-100) | ≥5 | 4~5 | 8~12 | 30 | |

| Y83-5000 | 450 | (φ110-φ140)×(70-100) | ≥5 | 4~5 | 10~14 | 37 | |

| Y83-6300 | 520 | (φ130-φ160)×(70-100) | ≥5 | 4~5 | 16~20 | 45 |

Pre-sale services: 1. Providing professional technical support. 2. Send the product catalog and instruction manual. 3. If you have any question please contact us online or send us email, we promise we will give you a reply at the first time! 4. Personal call or visit are warmly welcome. Sale of services: 1. We promise honest and fair, it's our pleasure to serve you as your purchasing consultant. 2. We guarantee punctuality, quality and quantities strictly implement the terms of contract... After-sales service: 1. When to buy our products for one year warranty and life long maintenance. 2. 24-hour telephone service. 3. A large stock of components and parts, easily-worn parts.

Why choose us ? 1.We are the most reliable factory of hydraulic press for scrap recycling in jiangsu province ,China .2.Quality Control through the whole Manufacturing process.3.General Inspection and testing before Packing.4.Our products all passed ISO 9001.5.Service for long life time6.Many other Designs for you to choose and we can Accept minimum order. Your interests can be fully Guaranteed.7.After you make order, we will Follow up the whole process and Update it to you. Collecting goods, Loading containers and Tracking goods transport information for you.8.Any of our products you are interested, or any customized orders you wish to place, any items you want to buy, Please let us know your requirements. Our team will do our best to Help you .

1. 24-hour Online service Please feel free to contact us. Our sales team will provide you with 24 hours better before sale 2. Competitive price All of our products are supplied directly from factory. So the price is very competitive. 3. Warranty All products have a one years warranty. 4. OEM/ODMWith 20 years experiences in this field, we can provide customers with professional suggestion. To promote common development. 5. DistributorThe company now recruit distributor and agent all over the world. Prompt delivery and professional after-sales service are our priority, which makes us to be your reliable partner.

Prev: Auxiliary Equipment Steel/Cooper/Metal Wire Candid Sharpening Production Line Pointing Machine

Our Contact