Complete Set Quarry Granite Stone Crusher Plant, Portable Mining Limestone Gravel Concrete Jaw Crusher and Screening

Description

Basic Info

| Model NO. | SMC600, SMC750, SMC900, SMC1060 |

| Application | Construction |

| Materials | Limestone |

| Outlet Size | 150-300mm |

| Inlet Size | 1000×1200mm |

| Condition | New |

| Warranty | 1yers |

| After-sales Service | 1yers |

| Dimension(L*W*H) | According to The Model |

| Raw Material | Stones Rocks Ores |

| Keyword | Large Scale Jaw Crushing Plant |

| Color | Customizable |

| Quality | Advanced Technology |

| Advantage | High Efficiency Low Energy |

| Factory Visit | Welcomed Warmly |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Transport Package | Wooden Boxes, etc |

| Specification | 99.9 |

| Trademark | Baichy |

| Origin | China, Hanan |

| HS Code | 8474209000 |

| Production Capacity | 30-800 T/H |

Packaging & Delivery

Package size per unit product 2630.00cm * 2310.00cm * 3110.00cm Gross weight per unit product 200000.000kgProduct Description

Complete Set Quarry Granite Stone Crusher Plant, Portable Mining Limestone Gravel Concrete Jaw Crusher and ScreeningProduct Description

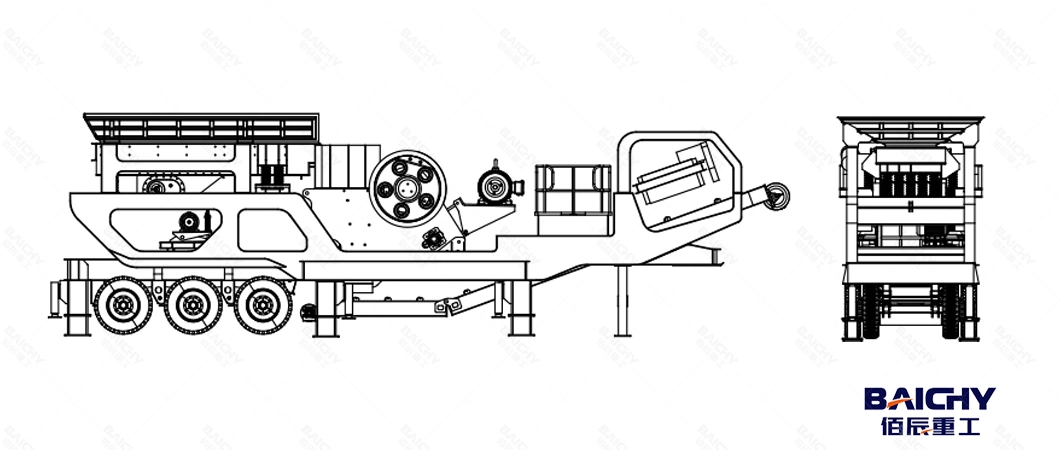

The mobile crushing station, also known as the tire-type mobile crushing station, is a new type of high-efficiency rock crushing equipment, which solves the limitation of the displacement space of the crushing operation and also solves the shortcomings of poor crushing mobility. The equipment does not have too many requirements for the crushing site and has a strong adaptability to the working environment. Baichy mobile crushing plant can be effectively applied to different material screening requirements, with excellent processing capacity and screening efficiency.

Product Advantage

The jaw mobile crushing station has strong operation coordination, integrated operation, more investment savings, lower energy consumption, and has the advantages of small size, reliable operation, small turning radius, and convenient road driving. It is widely used in the operation of mobile stone materials such as roads, railways, and hydropower projects.

Baichy machinery will be configured differently according to customer requirements. The company has professional technicians to provide customers with suitable machinery and equipment.

Applied Material

The mobile crushing station is mainly used in metallurgy, the chemical industry, building materials, roads, mining, and other industries, especially roads, railways, construction waste, and other fields that need to relocate and process materials and can achieve coarse crushing, medium crushing, and fine crushing. It can meet the needs of different fields.The stone crusher is used to crush more than 120 kinds of rocks such as limestone, granite, quartz, basalt, river stone, gold mine, iron mine, coal, crushed stone, aggregate, etc. Different final output sizes can meet your different needs.

Working Principle

Mobile jaw crushing station includes a vibrating feeder, stone crusher, vibrating screen, belt conveyor, motor, control box, etc.The material is evenly conveyed into the crusher through the feeder. After the primary crushing by the jaw crusher, a closed circuit system is formed by the circular vibrating screen to realize the circular crushing of the material. The finished material is output by the conveyor for continuous crushing. The jaw crusher mobile crushing station can remove the circular vibrating screen according to actual production needs, so as to realize the direct primary crushing of materials, and it is convenient and flexible to use with other crushing equipment.

Technical Parameters

| Model | SMC600 | SMC750 | SMC900 | SMC1060 | SMC1200 | SMC1300PEX |

| Transport size | ||||||

| Length(mm) | 8600 | 9600 | 11097 | 13300 | 15800 | 9460 |

| Width(mm) | 2520 | 2520 | 3759 | 2900 | 2900 | 2743 |

| Height(mm) | 3770 | 3500 | 3500 | 4440 | 4500 | 3988 |

| Alex weight(kg) | 10121 | 14500 | 21380 | 38430 | 64000 | 14730 |

| King pin weight(kg) | 5118 | 7500 | 10890 | 19450 | 34000 | 10490 |

| Jaw crusher | ||||||

| Model | PE | PE | PE | PE | PE | PEX |

| Feed opening(mm) | 400X600 | 500X750 | 600X900 | 750X1060 | 900X1200 | 300X1300 |

| Discharging hole setting range(mm) | 40-100 | 50-100 | 65-180 | 80-180 | 95-225 | 20-90 |

| Capacity(t/h) | 15-60 | 40-110 | 90-180 | 110-380 | 220-450 | 30-105 |

| Feeder | ||||||

| Feed hopper volume | 3 | 4 | 7 | 10 | 10 | 3 |

| Hopper width | 2200 | 2500 | 3000 | 3000 | 3000 | 2200 |

| Model | ZSW6520 | ZSW8530 | ZSW9638 | ZSW1142 | ZSW1349 | ZSW8530 |

| Belt conveyor | ||||||

| Model | B650X6 | B800X7 | B1000X8 | B1000X11 | B1200X13 | B1000X7 |

There are many different classifications and multi-machine combinations of mobile crushing stations, mainly crawler-type, and tire-type. Each classification can be divided into jaw mobile crushing station, impact mobile crushing station, mobile sand making machine, cone crusher, and other types according to the different crushing systems. The functions of each crushing station have certain differences, and customers can choose according to the type and scale of processed raw materials and the requirements of finished materials.

Baichy Mobile crushing station has a complete range of models, and we have professional designers who can customize suitable solutions for you.

Company Profile

Baichy headquarters is located in the industrial park in Jiaozuo City. It covers a total area of 200,000 square meters, including 150,000 square meters of standardized workshops. There are more than 200 sets of various large and medium-sized metal processing lathes, riveting machines, welding equipment, and assembly equipment. We have more than 500 workers, including more than 20 middle and senior technicians. Baichy is mainly focused on 4 series of products: stone crusher machines, sand-making equipment, powder grinding mills, mineral processing equipment, and their spare parts. Every year, Baichy can turn out 1,000 sets of crushers and 10,000 tons of crusher parts.

Through the international mining machinery exhibitions, We have demonstrated our professional equipment, technology, and thoughtful service to customers from all over the world.

Baichy always adheres to the "quality assurance, sustainable development" of the enterprise purpose and "customer first, mutual benefit and win-win" as the business principle.

FAQ

1. Are you a manufacturing or trading company?We are a factory, established in 2003.2. How long is your delivery time?7-10 days for the stock, 15-30 days for the mass production.3. What is your payment method?30% deposit in T/T advance, 70% balance before shipment.4. How long is the warranty? Does your company supply the spare parts?One year. Spare parts for you at the lowest cost.5. If I need the complete crushing plant can you help us to build it?Yes, we can help you set up a complete production line and give you related professional advice. We had already built many mining projects in China & Overseas.

Our Contact