24X36 Jaw Crusher for Staionary and Mobile Gravel Making Plant

Introduction of Jaw Crusher Jaw Crusher has been widely used in the fields of mining, metallurgical, construction, road

Description

Basic Info

| Model NO. | PE600X900 |

| Finished Surface | Outer Surface Process |

| Certification | CE, ISO |

| Condition | New |

| Color | Blue |

| Transport Package | Nude Packing |

| Specification | PE600X900 |

| Trademark | ANVIK |

| Origin | Henan |

| HS Code | 8474209000 |

| Production Capacity | 100sets/Year |

Product Description

Introduction of Jaw CrusherJaw Crusher has been widely used in the fields of mining, metallurgical, construction, road and railway building, hydropower and chemistry etc. It is mainly applied in the primary crushing in which the compressive strength of original material is under 320Mpa.

Main Features and Benefits

1. Simple structure and easy maintenance.

2. Stable performance and low operating cost

3. Flexible discharge opening setting

4. High resistance to friction, abrasion and compression with longer operating life span.

Operating Principle

This jaw crusher uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track. Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and side-lee board can be crushed and discharged through the discharging opening.

Specifications

| Model | Size of Feed Opening(mm) | Max Feed Size (mm) | Discharge Range Opening (mm) | Capacity (t/h ) | Motor Power (kw) |

| PE-150X250 | 150X250 | 125 | 10-40 | 1-3 | 5.5 |

| PE-250×400 | 250×400 | 210 | 20-60 | 5-20 | 15 |

| PE-400×600 | 400×600 | 340 | 40-100 | 15-60 | 30 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-100 | 55 |

| PE-600×900 | 600×900 | 500 | 65-180 | 60-140 | 75 |

| PE-750×1060 | 750×1060 | 630 | 80-180 | 90-230 | 90 |

| PE-900×1200 | 900×1200 | 780 | 95-225 | 150-350 | 110 |

| PE-1000×1200 | 1000×1200 | 850 | 195-280 | 180-400 | 132 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 160 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 5-16 | 15 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 10-40 | 22 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 15-50 | 37 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-60 | 45 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 25-95 | 55 |

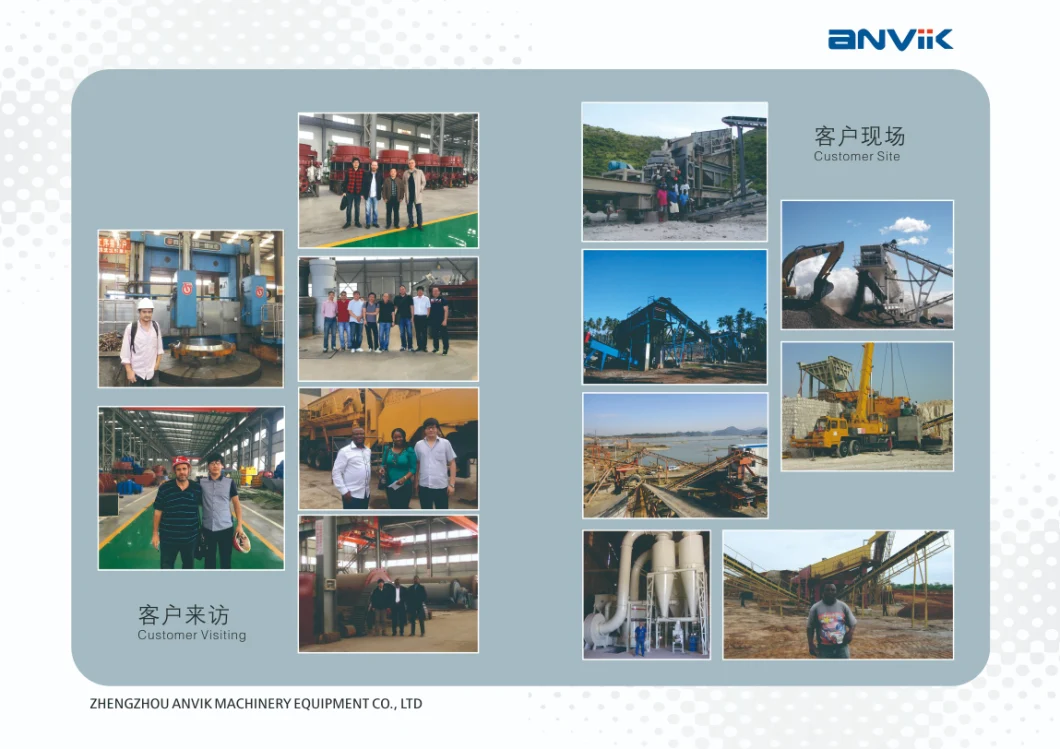

Photos at Our Factory

Our Contact

Send now